MAKING APERTURES FOR PEEPS

- contender1121

- Class C

- Posts: 189

- Joined: Mon Oct 23, 2017 11:43 am

- IHMSA Member#: 57830

- Location: Central Oklahoma

MAKING APERTURES FOR PEEPS

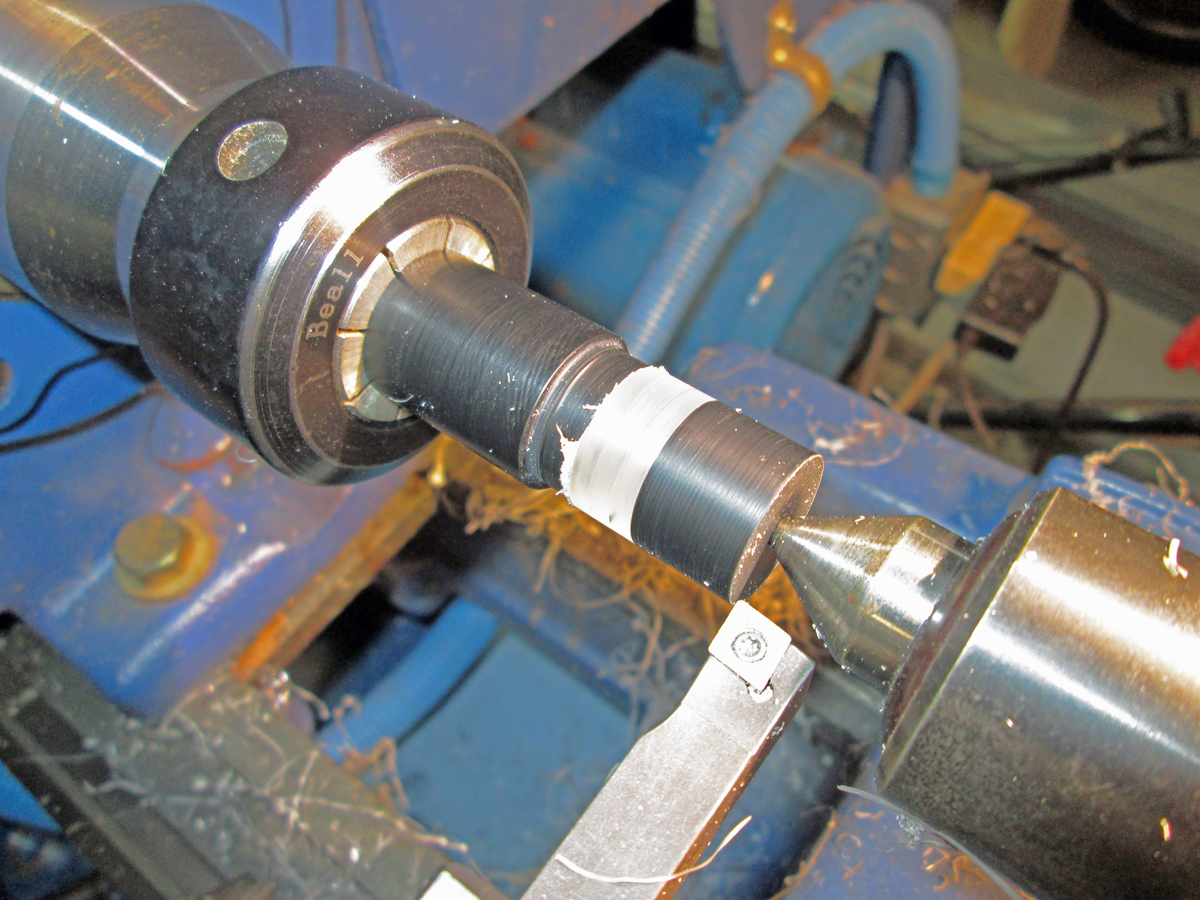

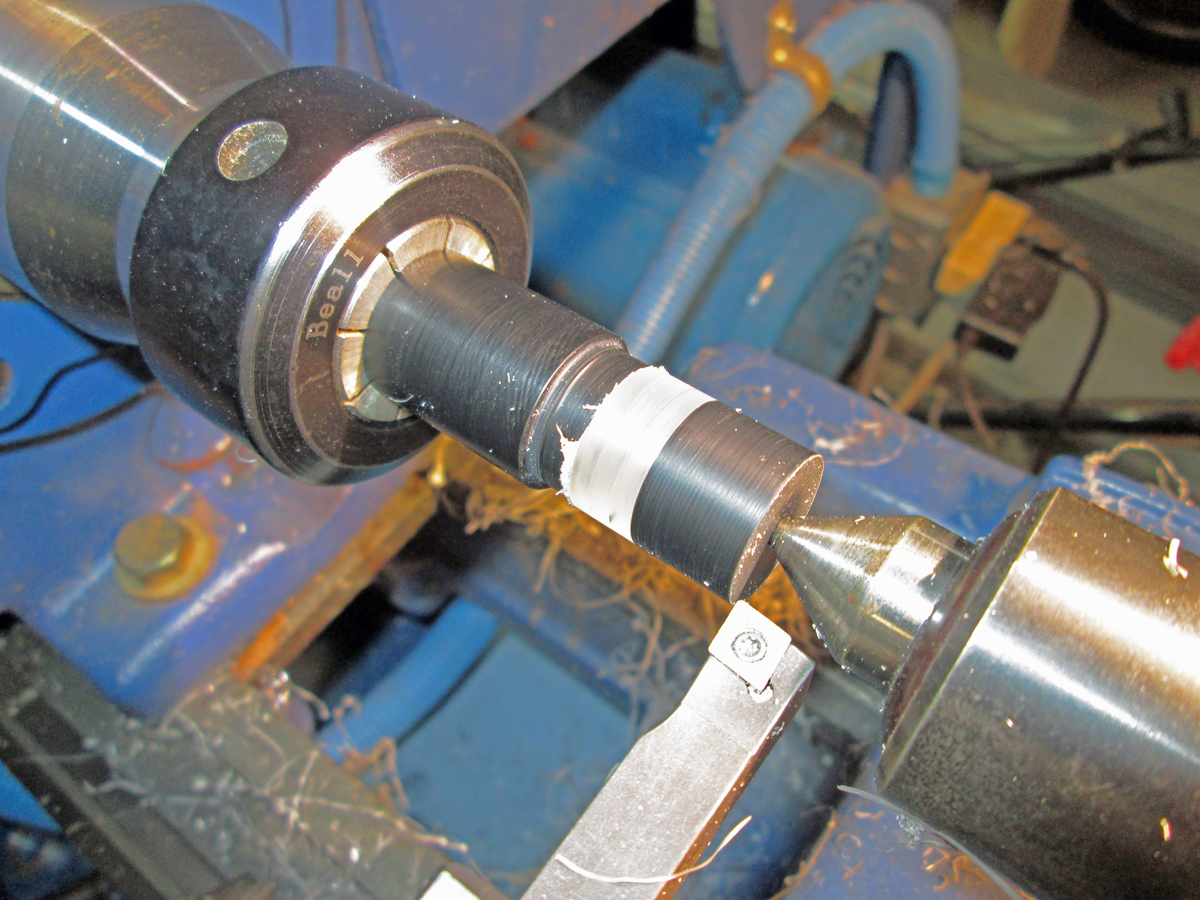

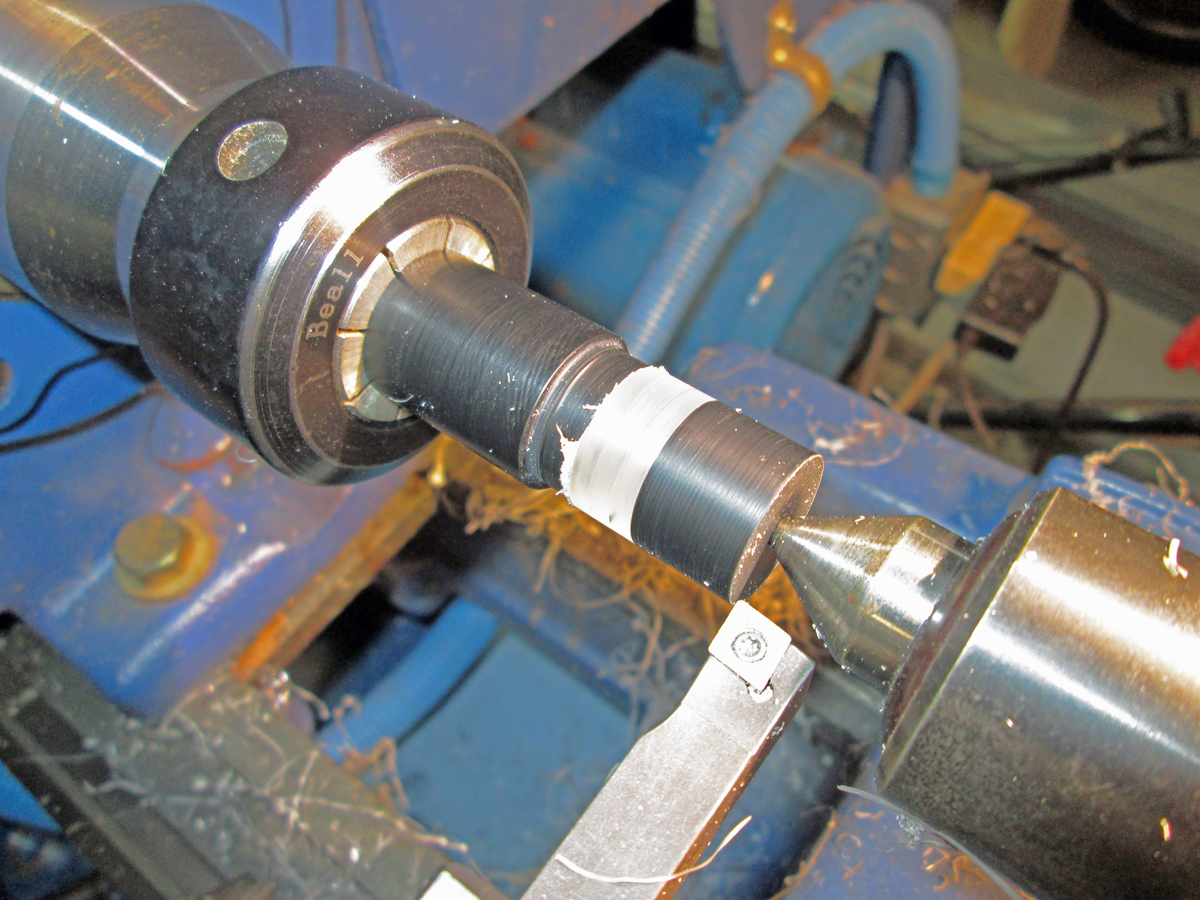

Turning acrylic between centers for peep sight apertures.

Re: MAKING APERTURES FOR PEEPS

Interesting. How do you make the faces of the acrylic smooth and clear?

Melvin

Melvin

Co-Match Director LRGC, Lincolnton, GA

- contender1121

- Class C

- Posts: 189

- Joined: Mon Oct 23, 2017 11:43 am

- IHMSA Member#: 57830

- Location: Central Oklahoma

Re: MAKING APERTURES FOR PEEPS

I start with cast (not extruded!) acrylic sheet and I leave the factory masking on. I next cut it into small squares and drill a .093 pilot hole in the center and stack them on a .093 dowel pin. I usually saw the corners off of the squares to make turning a little quicker and less likely to catch. The lathe jig is two pieces, made from a piece of cast acrylic rod. Each piece has a .093 hole drilled in the center to accept the pin. One half gets chucked in a collet on the headstock and the other piece become a clamp block at the tailstock. I use a ball bearing live center to make contact with the clamp block. Clamp and turn to the desired diameter. What you see in the pic is a stack of three pieces being turned.

After turning I open the hole up in the plastic with a chucking reamer and install a metal insert I make with the peephole in it. I am partial to this method over beveling one side of the hole in the plastic. I feel contrast is better (my opinion).

After all this, I peel off the factory masking and they are ready to go.

After turning I open the hole up in the plastic with a chucking reamer and install a metal insert I make with the peephole in it. I am partial to this method over beveling one side of the hole in the plastic. I feel contrast is better (my opinion).

After all this, I peel off the factory masking and they are ready to go.

Re: MAKING APERTURES FOR PEEPS

I would love to see a completed one with the metal insert.

How thick do you make them?

Thanks

Melvin

How thick do you make them?

Thanks

Melvin

Co-Match Director LRGC, Lincolnton, GA

- contender1121

- Class C

- Posts: 189

- Joined: Mon Oct 23, 2017 11:43 am

- IHMSA Member#: 57830

- Location: Central Oklahoma

Re: MAKING APERTURES FOR PEEPS

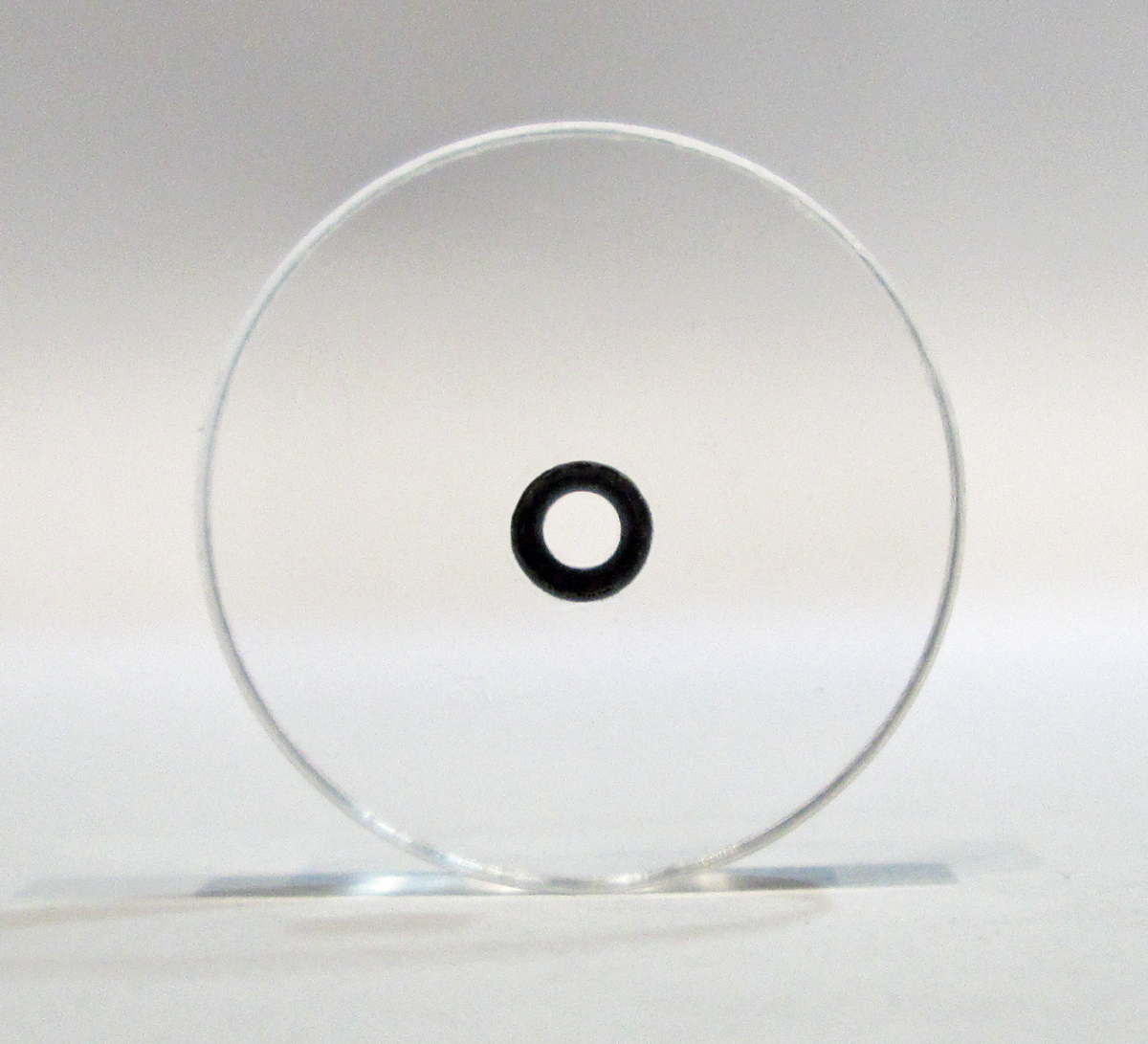

One thing about cast acrylic is that it can vary somewhat from its specified thickness. The piece from which I am working is .125 nominal but is averaging about .110. I like the .125 nominal material as it has enough meat to make sure the insert goes in straight. Of the three I cut in this pic, one has been installed. I need to make the inserts for the other two (soon). When I do, I'll get a pic for you.

The thickness of the acrylic is not critical as the insert is doing the work. I am in the midst of experimenting somewhat to determine the optimal length of the insert. You don't want it too long or it is conceivable that you will not retain a round hole visually if your sight adjustments are on the extreme side. Making the inserts is a bit delicate, being so tiny. Again, I'm experimenting. The truth may very well be that the insert is more trouble to make than it is worth. This type of aperture/insert can be purchased from Champions Choice but the hole and surrounding black ring are way too big in my opinion (personal testing). They are made for rifles with a lot longer sight radius. The hole I'm drilling in these right now is .070 (#50 drill). This makes the ring .0275 wide. Fine tuning all of this may be necessary after a trip to the range. I am an aerospace engineer (retired) I enjoy tinkering and the reason I'm messing with this is that under certain conditions I've had the ring wash out and lose some contrast, with the inserts that have the beveled hole. No such issues with an insert. I also plan on testing making the insert from black acrylic or Delrin instead of aluminum which needs to be blackened (pain in the arse).

Onward and upward.

The thickness of the acrylic is not critical as the insert is doing the work. I am in the midst of experimenting somewhat to determine the optimal length of the insert. You don't want it too long or it is conceivable that you will not retain a round hole visually if your sight adjustments are on the extreme side. Making the inserts is a bit delicate, being so tiny. Again, I'm experimenting. The truth may very well be that the insert is more trouble to make than it is worth. This type of aperture/insert can be purchased from Champions Choice but the hole and surrounding black ring are way too big in my opinion (personal testing). They are made for rifles with a lot longer sight radius. The hole I'm drilling in these right now is .070 (#50 drill). This makes the ring .0275 wide. Fine tuning all of this may be necessary after a trip to the range. I am an aerospace engineer (retired) I enjoy tinkering and the reason I'm messing with this is that under certain conditions I've had the ring wash out and lose some contrast, with the inserts that have the beveled hole. No such issues with an insert. I also plan on testing making the insert from black acrylic or Delrin instead of aluminum which needs to be blackened (pain in the arse).

Onward and upward.

- contender1121

- Class C

- Posts: 189

- Joined: Mon Oct 23, 2017 11:43 am

- IHMSA Member#: 57830

- Location: Central Oklahoma

Re: MAKING APERTURES FOR PEEPS

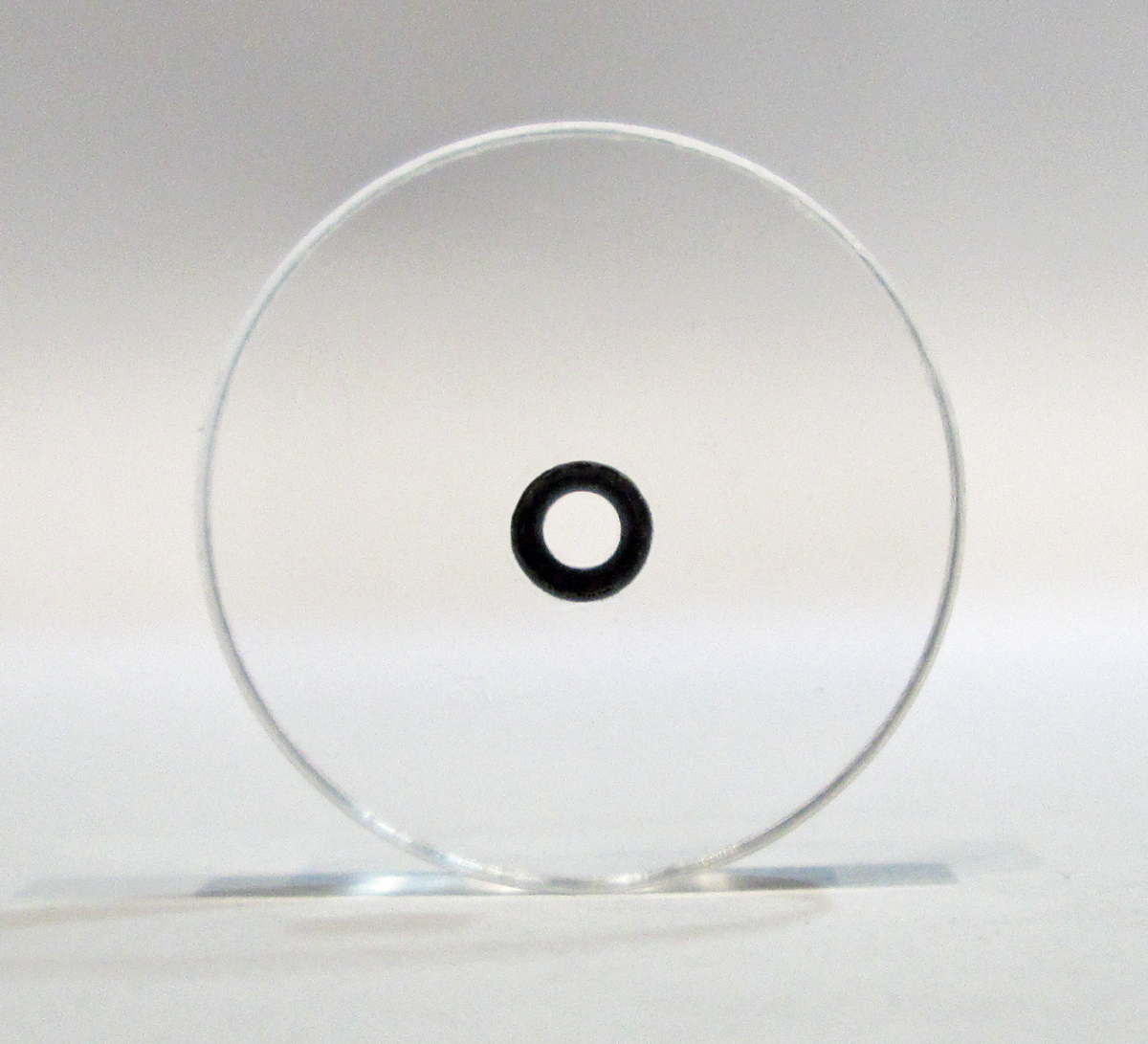

Just made this one and used black Delrin for the insert. I'm going to do another with black acrylic. Delrin machines like butter but it tends to be "stringy" and something this small is a SOB to deburr. The hole is .070 and the O.D. of the insert is .125. O.D. of the whole disc is .682.

- contender1121

- Class C

- Posts: 189

- Joined: Mon Oct 23, 2017 11:43 am

- IHMSA Member#: 57830

- Location: Central Oklahoma

Re: MAKING APERTURES FOR PEEPS

Thanks, much appreciated.

Re: MAKING APERTURES FOR PEEPS

FYI, I use .059 aperture on my B.B.standing and FP guns. I use .043 on my SB standing gun.

What holds the Delrin insert in place?

Thanks

Melvin

What holds the Delrin insert in place?

Thanks

Melvin

Co-Match Director LRGC, Lincolnton, GA

- contender1121

- Class C

- Posts: 189

- Joined: Mon Oct 23, 2017 11:43 am

- IHMSA Member#: 57830

- Location: Central Oklahoma

Re: MAKING APERTURES FOR PEEPS

In my case, they are press fit since Delrin is extremely difficult to glue. I'm dealing with small bore so I'm not concerned with recoil. I doubt it would be an issue with BB since there is no mass and the fit is tight.

Since making this one I've decided to go down in the diameter of the aperture. Things get a bit difficult on turks and rams with this big of a hole.

If I can figure a way to pull it off, I would like to try a very thin small ring with no hole at all. Who knows, it might work.

Since making this one I've decided to go down in the diameter of the aperture. Things get a bit difficult on turks and rams with this big of a hole.

If I can figure a way to pull it off, I would like to try a very thin small ring with no hole at all. Who knows, it might work.